Electrical braking for reduced braking time

Used In:

- High demand braking time application

- High inertia application

Used In:

Dynamic braking is a technique for electrical motor braking. The mechanical energy is converted to heat or electrical energy in order to slow and stop the motion.

With conventional braking systems, when the servo amplifier output power shuts off, the motor acts as a generator and converts the kinetic energy of the rotating motor and load into electrical energy.

Elmo’s highly reliable servo drives are design to reduce the servo braking time and dissipate the return energy from the motor when power off, by shortening all motor phases (to ground) while the drive is in Disable Mode

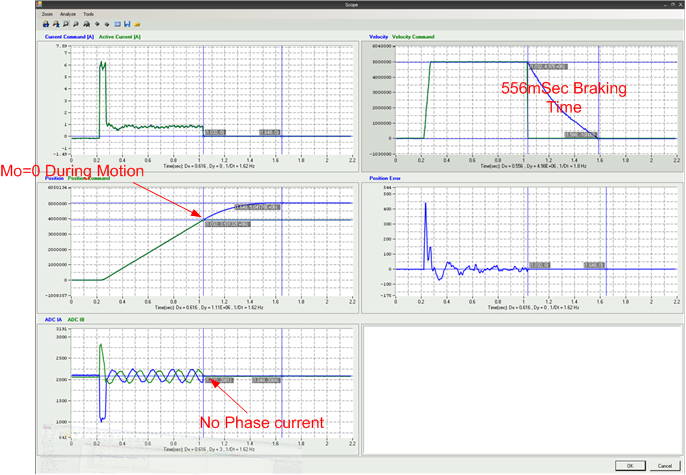

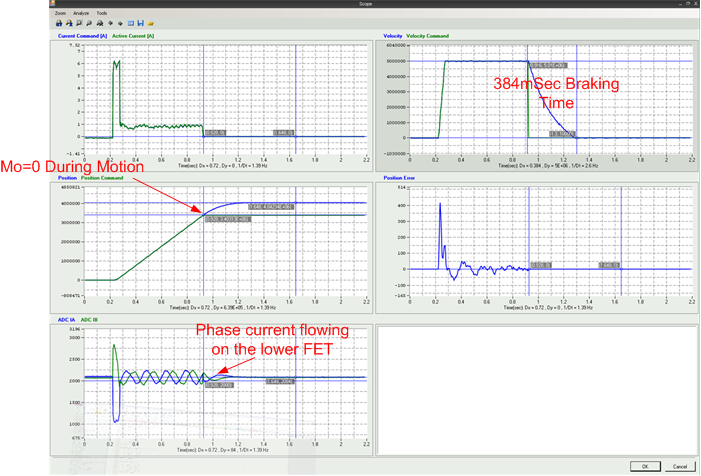

The following graphs shows motor braking results time with and without a dynamic braking.

Mo=0 command during motion, without dynamic brake test results

* MO =0 – Servo is off

With dynamic braking

Mo=0 command during motion with dynamic brake implementation

For more information please contact our motion control experts.

Thank you for your interest. Please fill in the form and we will get back to you shortly

Thank you for your interest. Please fill in the form and get access to the requested material